In today’s fast-paced world of medical diagnostics, accuracy and efficiency are non-negotiable. A single mistake in patient identification or specimen labeling can lead to wrong results, delayed treatment, and even compromised patient safety. Despite advances in technology and laboratory information systems (LIS), the foundation of every test still begins with one simple step: proper labeling.

Recently, I experienced firsthand how a small error in labeling created a bigger issue for our laboratory. It was a lesson not only about the role of technology but also about the responsibility of each technician in ensuring that samples are handled with care and precision.

You may like this : What is Procalcitonin Blood Test Used For? A Complete Guide for South Asian Countries like Bangladesh and India

The Problem: A Barcode That Wouldn’t Work

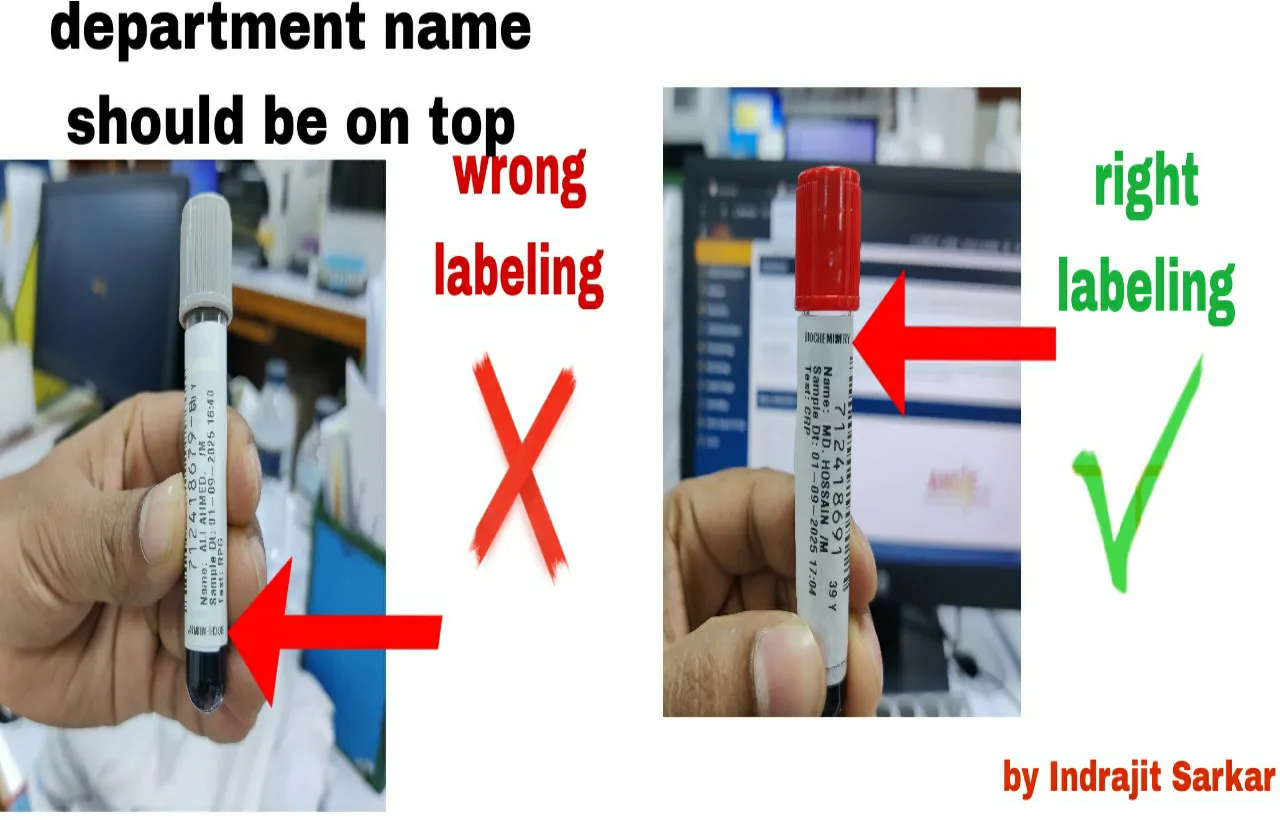

One day, our pathology department encountered repeated problems with barcodes not being read correctly by the analyzer. At first glance, the issue seemed like a technical fault—maybe a machine error or a LIS connectivity problem. But on closer inspection, I noticed that the root of the problem was surprisingly simple: incorrect labeling.

The department had been placing stickers upside down on the sample tubes. As a result, the barcode scanner could not interpret the information, leading to workflow disruptions and delayed reporting.

It wasn’t a malfunction of the machine at all—it was a basic labeling error.

The Fix: Creating a Template for Proper Labeling

Once the cause was identified, I corrected the alignment of the barcodes, making sure they were placed in the correct orientation. This immediately solved the scanning issue. To prevent future problems, I went one step further: I created a clear labeling template and shared it with the department.

The template explained where and how to place the stickers so that the barcode would always be readable by the machine. The fix was straightforward, yet it created a noticeable improvement. Yet, despite sharing this guideline, I noticed that some technicians were still struggling to adopt proper labeling practices.

Why Proper Labeling Matters

This experience highlights a larger issue that is often overlooked in many laboratories, especially in countries like Bangladesh. Some technicians, even with 10–20 years of experience, may still lack training in the basics of barcode labeling. Here’s why proper labeling is so important:

- Patient Safety

If a sample is mislabeled, there’s a risk that test results could end up linked to the wrong patient. In clinical practice, this can have life-threatening consequences. - Efficiency in Workflow

Laboratory instruments and LIS platforms are built to work quickly, but when a barcode fails to scan, it slows the process and adds extra pressure on staff. - Error Reduction

Typing in patient information by hand raises the chance of mistakes during data entry. Proper barcoding eliminates this step, reducing mistakes and improving accuracy. - Accountability

Labeling isn’t just about sticking a barcode on a tube—it’s a responsibility. Each technician’s attention to detail reflects the professionalism of the entire lab.

The Bigger Picture: Training and Awareness

The story of the upside-down sticker isn’t just about one department; it reflects a wider need for training and awareness in laboratory practices. Technology can only function as well as the humans who use it. Without proper training, even the most advanced LIS or analyzer cannot guarantee accurate results.

It’s surprising, but true, that some highly experienced technicians are unfamiliar with correct labeling standards. This is not due to lack of dedication, but rather due to gaps in structured training programs and standardized operating procedures.

you can also read : D-Dimer Test: What It Is and Why Doctors Recommend It

Moving Forward

The lesson from this incident is clear: laboratories must prioritize proper labeling as a core competency. Regular workshops, visual templates, and hands-on training should be part of every lab’s quality assurance program.

For me, fixing the barcode problem wasn’t just about solving a technical glitch—it was about realizing that even the smallest errors in routine tasks can have significant impacts. And while technology is advancing rapidly, the foundation of accurate diagnostics still depends on human responsibility and attention to detail.

Proper labeling may seem like a minor step, but in the chain of medical diagnostics, it is one of the most critical links. By improving this simple practice, laboratories can save time, avoid errors, and most importantly, safeguard patient health.

more on our fb so stay up to date with oviggobd

নতুন কিছু শিখতে চাই এবং সেখাতে চাই । অনভিজ্ঞও থেকে আপনিও হয়ে উঠুন অভিজ্ঞ।